Eaton to Collaborate on Cybersecurity with UL

February 24, 2018

Eaton’s collaboration with UL will help to establish measurable cybersecurity criteria for network-connected power management products and systems.

Through UL’s Cybersecurity Assurance Program, Eaton, UL and other industry organizations are working together to establish foundational requirements for testing of network-connectable industrial control systems to enable protection against vulnerabilities and security risk controls.

“We seek to help manufacturers, their customers and other stakeholders mitigate security risks through science-based assessment and evaluation,” says Ben Miller, president of the Commercial and Industrial business unit of UL. “Our collaboration with experts at Eaton is providing some of the crucial inputs to developing the technical expertise for new standards, and it’s helping advance UL’s efforts to protect our world’s critical infrastructure against ever-increasing cybersecurity threats.”

Eaton’s cybersecurity research and testing facility in Pittsburgh is the first lab approved to participate in UL’s Data Acceptance Program for cybersecurity. The program, which is in development and available on a limited basis, aligns Eaton’s testing methodologies and data generation with the UL Cybersecurity Assurance Program for UL Standards 2900-1 and UL 2900-2-2.

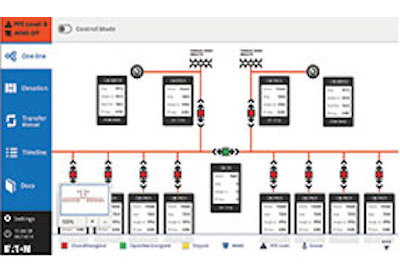

Eaton’s research and testing facility now has the capability to test Eaton products with intelligence or embedded logic to key aspects of the UL 2900-1 and 2900-2-2 Standards. Through this environment and Eaton’s cybersecurity process, Eaton is developing a growing portfolio of products to meet stringent specifications, regulations and consumer expectations for safe, secure power management. (Shown in photo: screen shot of Eaton’s Power Xpert Dashboard, the first power management product certified to the UL 2900-2-2 Standard for cybersecurity in industrial control systems.)

Cybersecurity risk

Cybersecurity is one of manufacturing’s most critical risk factors, and the number of security incidents in this sector was nearly 40% higher than the average across all industries (source: 2017 IBM X0Force Threat Intelligence Index). While manufacturers continue to innovate and build safer and more secure technologies, assessing risk is critical as cyber-attacks become more complex and difficult to guard against.

“A connected world needs trusted environments, and as we introduce more and smarter technology that enables us to link more elements of everyday life, trust becomes increasingly important,” says Michael Regelski, senior vice president and chief technology officer for Eaton’s electrical business. “Eaton’s collaboration with UL further expands our commitment to continue advancing these new technologies and innovations, while building trust and ensuring the highest level of defence against emerging cybersecurity threats.”

In another milestone, Eaton’s Power Xpert Dashboard recently became the first power management product certified to the UL 2900-2-2 Standard for cybersecurity in industrial control systems. This user portal to Eaton’s switchgear enables customers to monitor, diagnose and control equipment from a location outside the arc flash boundary.