ENT – The New Standard for Electrical Installation Efficiency

November 17, 2025

By Alex Whalen, Category Manager for Electrical products at IPEX Electrical Inc.

Electrical Nonmetallic Tubing (ENT) continues to shift expectations for how conduit systems should be installed in buildings and how they should perform on a jobsite. ENT offers many significant advantages including faster installation, improved safety and reduction in injury potential, and enhanced long-term reliability. These are factors that directly and positively influence project timelines and costs.

Cor-Line® ENT features a corrugated design that makes it approximately 50% lighter than Rigid PVC Conduit which is already significantly lighter than metal conduit. Its flexibility eliminates the need for pre-made bends, solvent cement, or additional fittings such as elbows, couplings, and adapters. The conduit can be easily routed through slabs, walls, and ceilings, adapting seamlessly to complex layouts without the need for specialized tools.

Kwikon® connectors utilize a locking-tab mechanism to create a concrete-tight joint suitable for embedded installations. This is achieved using an instant snap-in connection method featuring 6 locking tabs that easily meet CSA requirements for pull-out, which significantly reduces installation time.

In contrast, traditional conduit systems, such as Rigid PVC Conduit, require additional steps and materials. Solvent cement is needed, along with an applicator to create a proper joint, as well as a necessary curing time. For traditional metal systems, Electrical Metallic Tubing (EMT) requires a screwdriver or tightening tool to secure it to a fitting, whereas Rigid Steel Conduit requires a wrench, pliers, or another tightening method to ensure a secure threaded connection. ENT simplifies this process by allowing connections to be made in one motion, creating uniform joints without tools or additional preparation.

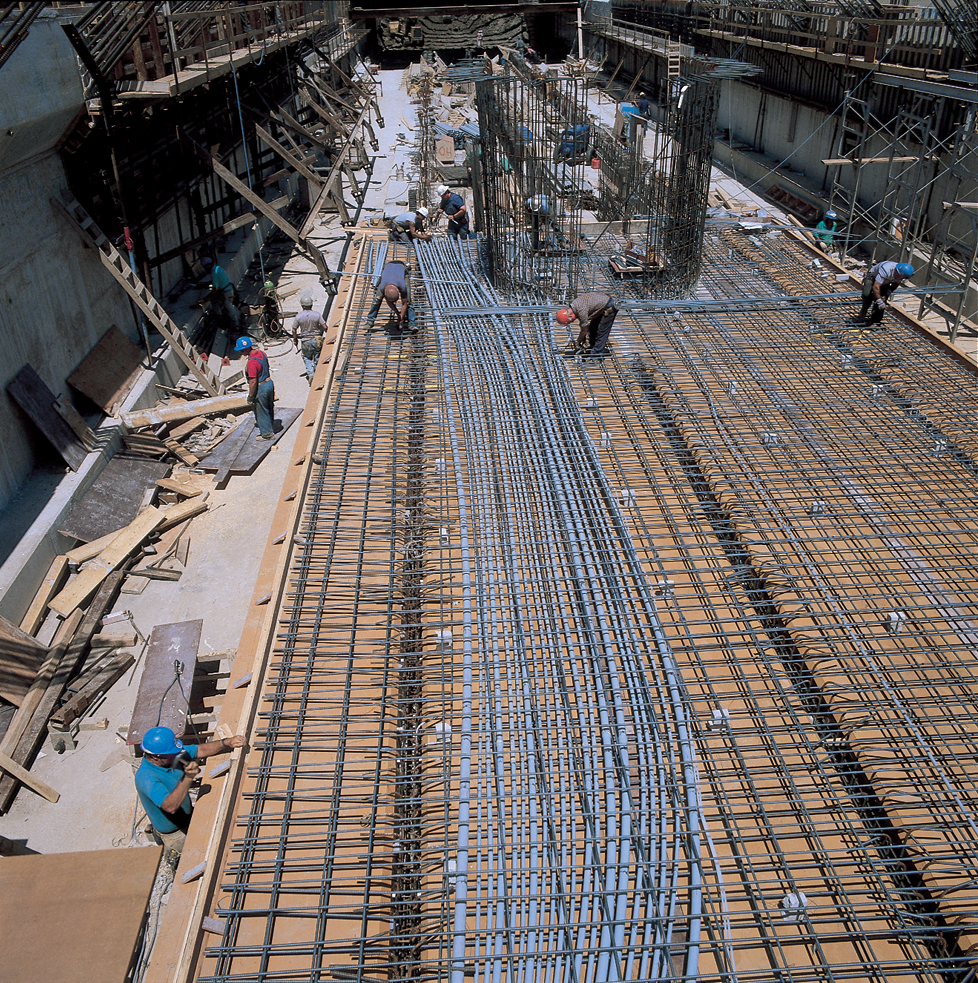

ENT is available in flexible, easy-to-transport coils and reels up to 1,500 feet, meaning fewer joints and couplings to install. Installers can pull long runs quickly, reducing both time and the number of connection points. More complex installations, involving multiple runs and directional shifts, such as high-rise concrete slabs and walls/ceilings containing structural components and other obstacles, can be maneuvered easily with ENT’s flexibility.

The lightweight materials simplify handling throughout the jobsite. Installers on jobsites can use the same practices as large cable reels by giving themselves the ability to pull conduit directly off the reel from one side of the installation site to the other. Availability of coils allows contractors to easily carry the conduit around in more closed installation settings (such as rooms, ceilings, walls, etc.) where large reels may be cumbersome. This reduces additional labor, as well as handling time and physical strain.

The same characteristics that improve installation also reduce production costs. ENT’s lighter weight and reel packaging lower transportation expenses and can reduce the number of trips needed to deliver materials to the jobsite. The result: a more efficient and lower-emission shipping process.

Cutting is also easily accomplished in a matter of seconds using a simple blade cutter, whereas conventional systems require more time and often involve multiple pieces of equipment. ENT can always be cut to exact lengths, which minimizes offcuts and potential scrap, rendering it a very environmentally friendly conduit system. Continuous runs require fewer couplings and no pre-made bends, which reduces material inventory. Stub-down fittings eliminate the need to drill forms, reducing formwork and minimizing waste.

The tool-free assembly means no power tools are needed on-site. This reduces energy use, costs, and tool maintenance, resulting in substantial savings that can accumulate over time, particularly for large projects. The flexibility of ENT also eliminates the need for dedicated bending tools such as heat guns and conduit benders.

There are misconceptions regarding the limited use case of ENT. It is the manufacturer’s responsibility to inform contractors about the entire application scope and versatility of this system as permitted by the Canadian Electrical Code (CEC). While ENT is commonly used in high-rise concrete slabs, its flexibility and corrosion resistance make it suitable for other applications:

- All concrete encasements

- Frame wall, ceiling systems and other concealed applications

- Commercial and residential applications

- Schools, hospitals, parking structures, and stadiums/arenas

- Underground applications

*Underground applications are only approved in Canada and require ENT to be solvent welded to rigid PVC fittings. Local/provincial code authorities should be consulted to confirm permitted uses.

Remember, ENT connectors are concrete-tight; however, if a watertight joint is required or if ENT fittings with push-in connectors are unavailable, ENT can be solvent welded to regular Rigid PVC Fittings. It is recommended that when needing to solvent weld Cor-Line ENT that Scepter Rigid PVC Fittings be used to ensure proper manufacturing tolerances and specifications are followed.

Across Canada, ENT has established itself as a practical standard for electrical installation. ENT isn’t changing the installation. Instead, it is changing how installations are done in an effective, sustainable, and lower complexity manner.

About the author:

Alex Whalen is the Category Manager for Electrical products at IPEX Electrical Inc. He has worked in the thermoplastic piping industry for 5 years (all with IPEX), gaining knowledge of product features, certifications and proper applications. Alex received his Bachelor’s Degree in Chemical Engineering from McGill University in 2019.