CSA 343: What Every Electrician Needs to Know About the New Standard for EVEMS

September 8, 2025

By David Corbeil, RVE CEO and Co-Founder

It’s official: the new CSA C22.2 NO. 343 standard has been published by the CSA Group. It officially regulates electric vehicle energy management systems (EVEMS) to allow for the partial or complete omission of electric vehicle charging equipment (EVSE) from the load calculation in Section 8 of the Code. Master electricians will find clear guidelines to ensure installations are compliant, safe, and easier to approve during inspections.

What is CSA 343?

CSA 343 is a performance standard for EVEMS. It certifies not only individual components such as charging stations or relays, but also the entire assembled system, including communication, software functions, and failure response. Its objective is to ensure that electric vehicle charging management systems are reliable, interoperable, and safe for users, buildings, and electrical grids.

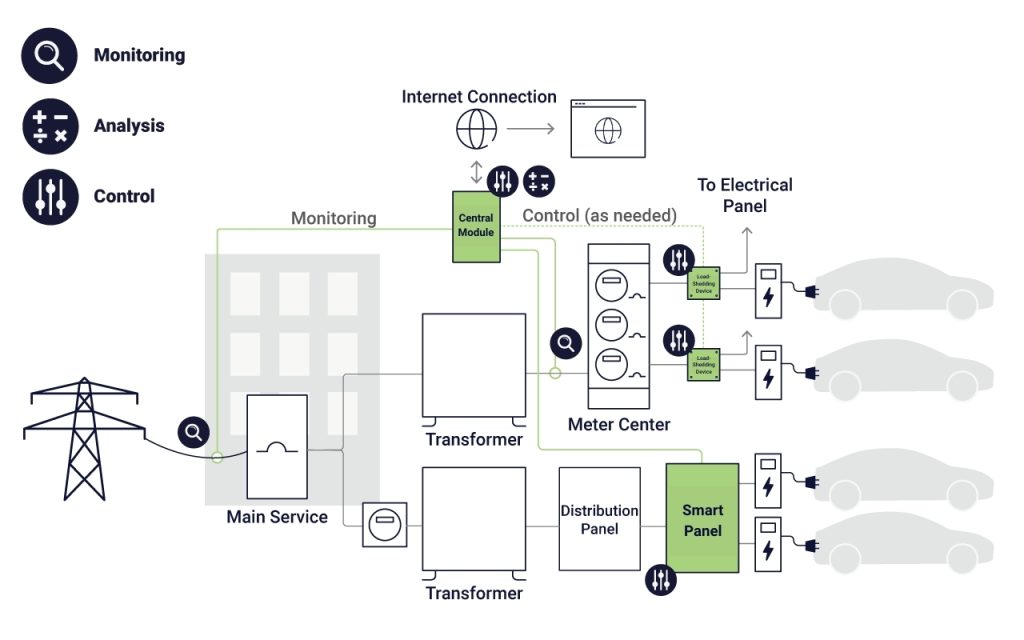

An electric vehicle energy management system monitors, analyzes, and controls the charging of connected vehicles.

Its American equivalent is the Outline of Investigation (OOI) UL 3141, a performance standard that aims to achieve the same general objectives. UL 3141 provides a comprehensive framework for the design of power control systems, requiring robust wired communications, local redundancy, and reliable management of failure scenarios. While CSA 343 applies specifically to electric vehicles, UL 3141 has a broader scope, making it an essential reference for manufacturers who want to offer versatile, resilient systems that are compatible with the expectations of AHJs (Authorities Having Jurisdiction) on both sides of the border.

These two standards can coexist: the same product or system can aim to comply with both standards in order to cover all markets and offer maximum guarantees to installers, inspectors, and end users.

Pre-Certified vs. Field-Assembled Systems

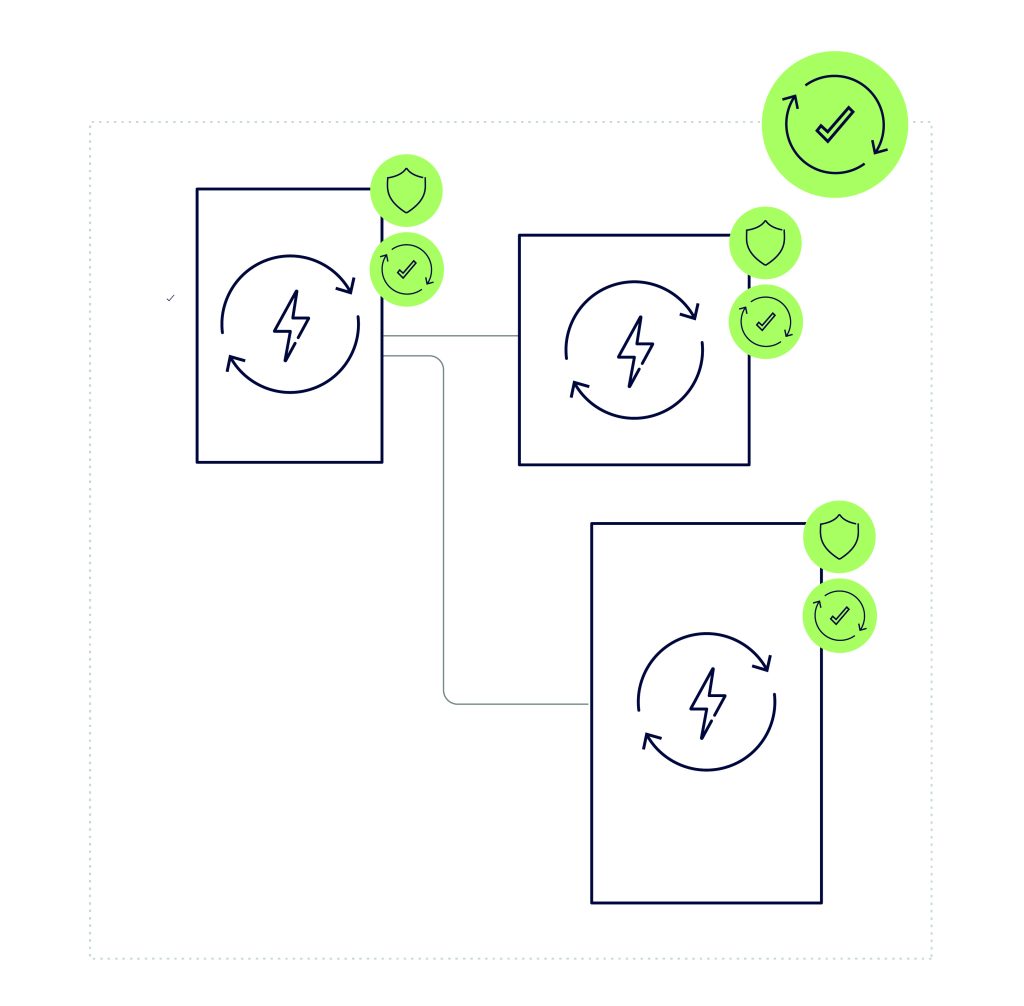

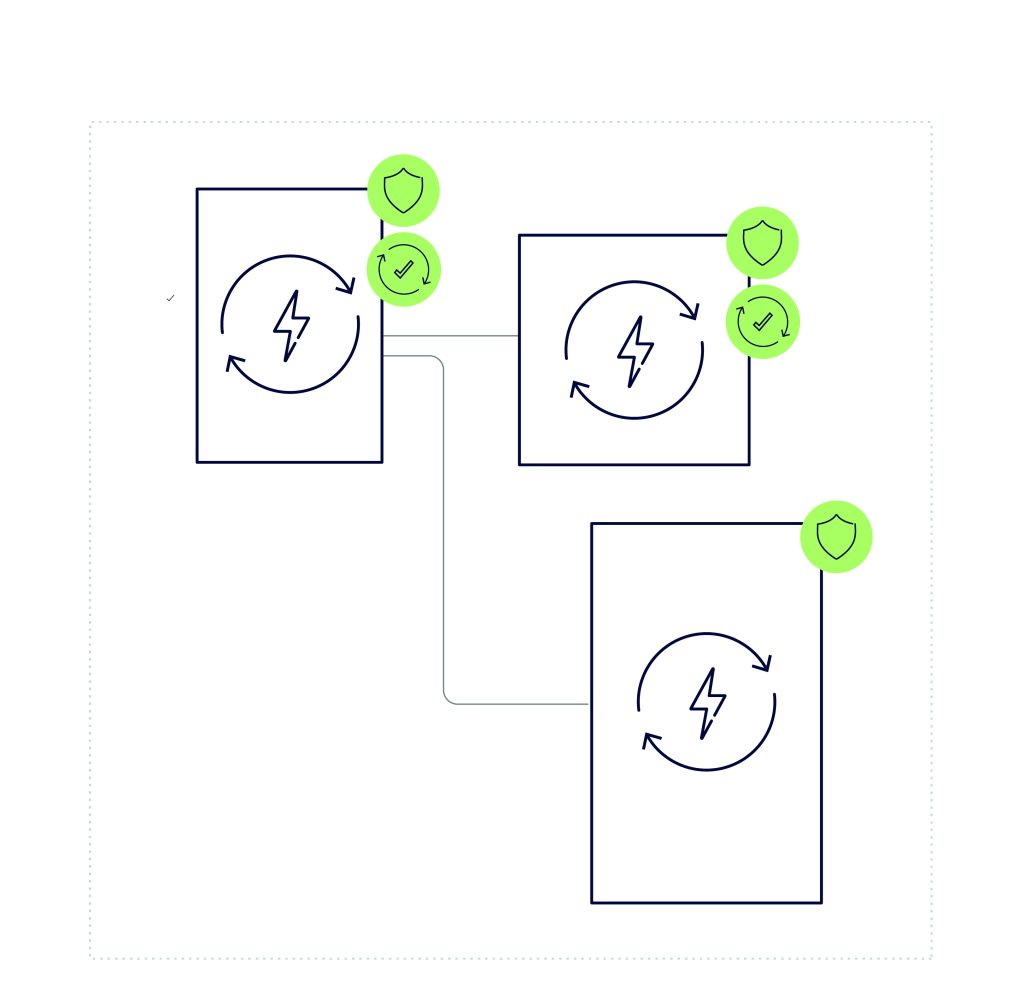

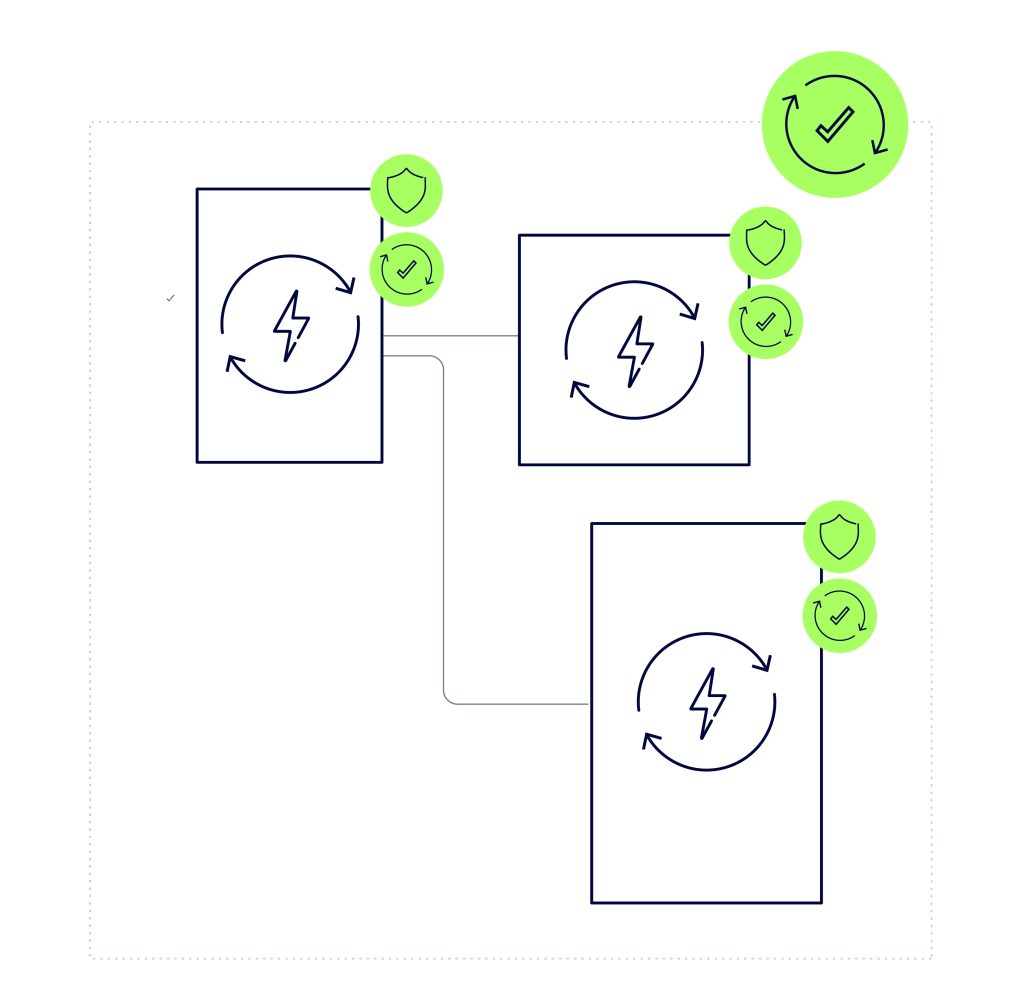

EVEMS come in two distinct forms, each with its own regulatory implications:

- Pre-certified systems: These are “all-in-one” products that have been tested and certified as a single complete unit.

- Field-assembled systems: These systems are created at the installation site by interconnecting several separately certified components.

The emergence of standards applicable to all systems, such as CSA C22.2 NO. 343 and UL 3141, creates an essential bridge between these two forms. When all components without exception of a system assembled on site are certified together according to this single standard, this allows the competent authority to approve it with the same confidence as a pre-certified system.

Safety standard vs. performance standard

In the electrical field, not all certifications are equal. It is essential to distinguish between safety standards and performance standards, as they do not protect against the same risks and do not imply the same responsibilities for the installer.

- A safety standard (such as CSA C22.2 No. 280, UL 2231, or any other “Listed” or “Recognized” certification) applies to each piece of equipment individually. It is intended to ensure that the product is safe: no risk of fire, electric shock, short circuit, etc. This is a basic requirement. No electrical equipment can be legally installed without this certification.

- A performance standard, such as CSA 343 or OOI UL 3141, goes further. It evaluates the operation of the entire system under real-life conditions. In other words, it does not just look at whether each component is safe on its own, but whether they interact reliably and safely when networked. This includes software decisions, communication between devices, dynamic load management, and, most importantly, behavior in the event of a failure.

A system can be made up entirely of safe equipment… without being efficient or compliant as a whole. In this case, it is the electrician who will be held responsible.

Why is this standard important for electricians?

CSA 343 primarily enhances facility safety by imposing clear requirements on interoperability, fault response, and intelligent load management. This ensures that EV charging systems are not only functional, but also reliable and compliant with the most stringent rules of the Electrical Code.

This standard also plays a key role in the allocation of responsibilities. When a product is CSA 343 certified, the competent authority can place its trust in it based on systemic tests carried out by a recognized body. On the other hand, if an electrician installs a system composed of non-certified enclosures and components, he or she assumes responsibility for the overall proper functioning of the system. The electrician must then provide evidence that the system meets all performance and safety requirements. System certification therefore becomes a professional protection tool for the installer.

Safety measures to remember

The standard establishes rigorous requirements to enhance the electrical safety of charging installations. Here are five essential requirements, illustrated with an analogy based on how elevators work.

1. Circuit overload prevention

EVEMS must be able to detect and correct potential or actual overloads in electrical circuits. A response time of less than 5 seconds is imposed depending on the configuration, guaranteeing rapid management to avoid the risk of fire or equipment failure.

Imagine a guard posted at the entrance to an elevator shouting: “Too many people! You’re not as light as you think!” EVEMS do the same thing: they make sure that the electrical capacity never exceeds its load limit, by loadshedding connected electric vehicles to prevent overloading.

2. Predefined fail-safe state

When discussing energy management systems for EVs, a critical aspect that is often overlooked is how the system responds in the event of a failure. This situation, known as the “fail-safe state,” has a direct impact on the calculation of the building’s total load.

If, in the event of a failure (loss of communication, software bug, etc.), the system completely shuts down the charging stations (fail-safe at 0 amps), the load of the EVSEs can be completely excluded from the load calculation. However, if the charging stations can remain partially active, even at low power (fail-safe > 0A), it becomes mandatory to add 100% of their rated current to the load calculation.

When an elevator breaks down, it locks between two floors to prevent free fall. EVEMS systems, on the other hand, switch to a fail-safe state, such as a complete power cut or a reduction in load to 0 amps, to prevent non-compliance with the applicable electrical code.

While smart panels and load shedding and monitoring devices can cut their power supply to 0 amps, networked charging stations will generally have a minimum threshold limited to 8 amps.

It is therefore crucial to consider the safety current in the event of a failure of the EVEMS when designing the electrical infrastructure required for charging electric vehicles.

3. Real-time load monitoring and control

Systems must include current monitoring devices (CT, or current transformers) to track the actual consumption of connected devices. The devices must measure consumption in real time, and must be located inside the building (operating system) to maintain safety features at all times.

It’s as if an invisible operator were checking the weight in the elevator every 5 seconds.

In the same way, EVEMS constantly monitor circuits, ready to intervene in less than 5 seconds in the event of critical load shedding.

4. Resilience of communication systems

EVEMS must be designed to monitor and manage communication interruptions. If a signal loss occurs, the system automatically switches to a safe state, eliminating any risk associated with an unexecuted command.

If an elevator’s buttons fail to respond, a good system will automatically call the technician. For EVEMS, if communication between devices is interrupted, they switch to a fail-safe state to avoid electrical overload.

Elevators don’t trust Wi-Fi to save lives. Similarly, EVEMS don’t trust the cloud to protect electrical infrastructure.

5. Safety of physical components and connections

Standards require robust protective enclosures for electrical components, capable of withstanding impact and heat. In addition, specific measures, such as flame resistance tests, ensure that the materials used do not pose a risk under abnormal conditions.

Just as an elevator is designed to withstand excess weight and power cuts, EVEMS must be designed in heavy-duty enclosures that can withstand the elements.

How can you recognize a compliant system?

A pre-certified system is factory tested as a single unit, such as a smart panel. This type of approach ensures that the system is recognized as safe and reliable as a whole, as it is validated by a recognized body according to performance standards. In contrast, a field-assembled system consists of several interconnected devices, which may be certified individually, but this does not guarantee that the whole will function safely when combined. This is where the major challenge lies: an assembly of individually certified components does not constitute a certified system.

Equipment certification is a fundamental requirement. Every electrical device installed must be approved by a recognized organization (CSA, UL, etc.), confirming that it meets the required safety and performance standards. However, beyond these individual certifications, certification of a complete system is often lacking in field-assembled EMSs.

This gap creates a gray area in terms of liability: the electrician must be able to demonstrate that the components, when combined, continue to behave safely and compliantly. If a single component in the ecosystem is not certified, the entire system is considered non-compliant, and the responsibility for proper operation rests entirely with the installer. This constitutes a significant technical and legal risk that only a system certification such as CSA 343 can adequately address.

CSA 343, a turning point for smart and safe charging

The publication of CSA Standard C22.2 No. 343 marks a milestone in the professionalization and safety of electric vehicle charging installations. It provides master electricians with a solid and concrete reference framework, shifting the focus from components to systems. This development is fully in line with the situation in Canada, where residential electrification is gaining momentum and requires more complex, but also smarter, installations.

EVEMS must meet strict requirements for reliability and accuracy. The CSA 343 standard introduces essential principles: quick overload detection, fail-safe management, real-time monitoring, robust communications, and durable components. These technical guidelines aren’t just recommendations—they’re a new foundation for designing infrastructure that’s sustainable, safe, and meets inspectors’ expectations.

For electricians, understanding and integrating CSA 343 also means regaining control of their professional responsibility: by installing a pre-certified system, they avoid bearing the burden of overall compliance alone. Conversely, assembling individually certified components on site that have not been tested together exposes them to technical and legal gray areas.

CSA 343 becomes the key tool for securing projects, facilitating inspections, and ensuring that every residential charging installation is based on a reliable and validated system.

Home Charging Solutions for Electric Vehicles | RVE