Structured Data, a Prerequisite for AI Electrical Manufacturers

April 17, 2024

By David Gordon, President, Channel Marketing Group

In the realm of electrical manufacturing, the potential of integrating Artificial Intelligence (AI) could be a competitive advantage.

One of the critical components underpinning the effectiveness of AI is structured data.

Structured data refers to organized information that is formatted for easy analysis and interpretation by machines. In the context of electrical manufacturers, structured data serves as the backbone for AI-driven processes, enabling manufacturers to streamline operations, enhance product quality, and drive innovation.

Here are reasons why structured data is indispensable for harnessing the power of AI:

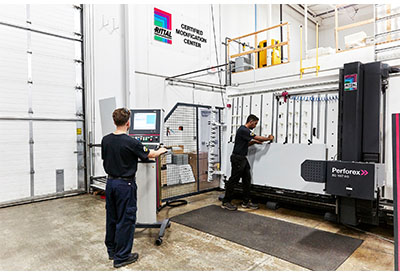

- Improved Efficiency in Production Processes: Structured data allows manufacturers to optimize their production processes by providing real-time insights into various aspects of their manufacturing operations. AI algorithms can analyze structured data from sensors, machines, and production lines to identify patterns, predict equipment failures, and optimize workflows. This proactive approach minimizes downtime, reduces maintenance costs, and maximizes the overall efficiency of production processes. Further, for project-oriented manufacturers, it could tie PO’s to where they are in the production process, enabling for real-time order tracking.

- Enhanced Product Quality and Reliability: By leveraging structured data, manufacturers can implement AI-powered quality control systems that detect defects, deviations, and anomalies during the manufacturing process. Machine learning algorithms trained on structured data can identify subtle variations in product specifications, ensuring that only high-quality products meet the required standards. Further, this can cascade to real-time monitoring and detection, predictive analytics for defect detection, quality assurance across the supply chain, and support continuous improvement through feedback loops while helping providing information for compliance and regulatory requirements.

- Data-Driven Decision Making: Structured data serves as the foundation for data-driven decision-making. AI algorithms can analyze large volumes of structured data from diverse sources, including supply chain data, customer feedback, and market trends, to generate actionable insights to support decision-making. Whether it is optimizing inventory levels, forecasting demand, or identifying new market opportunities, structured data empowers manufacturers to make informed decisions that drive business growth and competitiveness.

- Facilitation of Innovation and Product Development: Structured data fuels innovation by facilitating the development of new products and technologies. AI algorithms can analyze structured data from research and development experiments, customer feedback, and market trends to identify opportunities for innovation. Whether it is designing energy-efficient appliances, developing smart grid solutions, or integrating renewable energy technologies, structured data enables manufacturers to stay at the forefront of technological advancements and meet evolving customer needs.

As you can see, structured data becomes the backbone of AI. AI cannot succeed without data. To achieve a data-driven environment your data needs to be cleansed and structured, at least to some degree.

It’s the old adage of GIGO (garbage in, garbage out).

The electrical industry is known for, shall we say, varied definitions of data. This is where adherence to product data standards come in, and the best way to achieve this is to embrace standards that are widely adopted and have shown the ability to “grow” with changing times.

While structured data clearly facilitates the efficient use of AI in many factors of product production, it also benefits the downstream process of buying and selling those products.

Structured product descriptors, such as in the ETIM classification model, enable companies to manage, share and/or present technical product information to their downstream customers in a more efficient way.

- Product data management: The ETIM classification model provides a standardized way to manage technical product information, making it easier for companies to organize and maintain their product data. This is especially useful for companies that sell a large number of products across multiple channels and in multiple countries.

- E-commerce: ETIM can help companies sell their products more effectively online. By using standardized product descriptors, e-commerce platforms can more easily categorize and present products to customers, improving the customer experience and thus increasing sales.

- Interoperability: By using the same classification model across multiple organizations, companies can more easily share and exchange product information. ETIM can improve and simplify the exchange of information between stakeholders, such as manufacturers, distributors, contractors, engineering firms and other product influencers and buyers. This supply chain efficiency reduces errors and makes it easier for companies to do business with each other. By way of codification for each piece of data within the model, product information can be digitally exchanged in any language, through any platform.

- Regulatory compliance: In the electrical industry there are regulations that require companies to provide detailed technical information about their products. By using the ETIM model, companies can ensure that their product information is accurate, complete, and in compliance with regulations.

- Enhanced product data accuracy: When the sender and receiver of the data supports the ETIM model, wholesalers can ensure that the product data they are providing to their customers is accurate, up-to-date, and aligned with industry standards. Accurate and reliable product information is essential to the end user for making informed decisions and selecting the most suitable products for their projects.

- Efficient product selection and procurement: As the industry moves forward with the Energy Transition movement, it involves the adoption of new technologies and energy-efficient solutions. ETIM facilitates the integration of standardized product data into digital systems used by distributors and their customers. This integration allows for streamlining product selection and procurement processes. Electricians, contractors, and other stakeholders can easily search for and identify energy-efficient products based on their specific requirements, leading to more efficient and sustainable purchasing decisions. By incorporating ETIM’s standardized classification system into their product catalogs and digital platforms, distributors can clearly indicate the energy efficiency ratings and features of various products. This empowers customers to make environmentally conscious choices and encourages the adoption of energy-efficient technologies, which are crucial for achieving sustainability goals.

ETIM … The Key to Structured Data in the Electrical Industry

As part of a global standards organization, ETIM North America is striving to make is easier for our industry to find and select the right product for their needs, the first time, by bringing the classification model to manufacturers and distributors in North America.

As a non-profit member-based organization, ETIM North America is responsible for adapting the global classification model to accommodate the specific descriptors needed for products produced for the North American market. The terminology, grammar, and languages used in North America can be different than those used in other countries. Through the product expertise of ETIM NA, we are able to facilitate the identification of what needs to be adapted for our local market, enabling full adoption of the ETIM standard across the industry.

By adopting the model as part of their digitalization strategy, companies can consistently and efficiently communicate the flow of product information all the way through the channel, within North America, to any country outside North America and, perhaps more importantly, utilize the information to power their AI journey as the ETIM product codes become part of your AI nomenclature.

Pursuing AI requires

- Conceptualizing opportunities

- Envisioning the “how”

- Understanding your data today and developing governance models, and commonality, that allows capturing of information.

- Defining desired outputs

- Integrating / coding systems to achieve desired outcomes.

While it appears that the AI process is “simple”, the hard part starts when you lift the proverbial “hood” and say, “where do I start” and the answer is “data.”

Thoughts

- While AI may seemingly sound easy, your IT group is rolling its eyes and saying, “this could be hard.”

- AI is one of the reasons why product data standardization is important … and it should start with ETIM structured data.

- If you are not familiar with ETIM, contact Mary Shaw and/or visit etim-na.org (and no, you do not have to be an international company or involved in international commerce to be involved, you just need to want a better data future.

Take Aways

- Structured data plays a pivotal role in harnessing the potential of AI for electrical manufacturers. By organizing data, manufacturers can optimize processes, make informed decisions, drive innovation enhance customer service and potentially unlock new value-added benefits (and maybe services).

- If you are not already involved, reach out to find out how you can play a key role, alongside your peers, to help adapt the global model to meet our North American needs.